Works are underway to build in Getafe what will be the largest Spanish industrial plant dedicated to the production of the new European space launcher Ariane 6.

Airbus has begun to build in Getafe its new factory for the production of space systems, mainly Ariane 6, the new European launcher.

Airbus in Spain intends that the first phase of its new large production plant “can be opened within a year”, in order to meet the delivery deadlines required by the inaugural takeoff of Ariane 6, which is still set for July 2020.

Jose Guillamón, head of EO, Navigation and Science, together with his management team, laid the first stone of the new headquarters, which will have a production line with a high degree of digitalization according to the concept of industry 4.0.

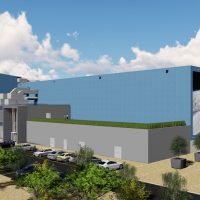

The newly designed plant is going to be built on a plot of 32,000 square meters. It will have two connected L-shaped buildings with a total of 20,685 square meters, including an area of 15,112 square meters for industrial works, a clean area of 4,069 square meters adapted to ISO 08 -and distributed in different clean rooms- , as well as a large administrative area of 1,500 square meters, all surrounded by an urbanized area of 11,300 square meters.

The company foresees that during the year 2019 some work areas will be able to be set up for the production of the Ariane 6 structures .

Airbus Space Systems in Spain has had to compete with industries in other countries to win Ariane 6 contracts, which include designing and manufacturing the inter-stage structure and payload adapters, equipment that it already manufactures for the Ariane 5.

For the Ariane 6 has also obtained the manufacture of the top of conical form of the accelerators of solid propulsion or ESR. with 3,5 tons of weight and 8 meters of height. The ESR are the propellers responsible for lifting the rocket from its launch ramp and propelling it into space during the first seconds of flight.

As it is a highly complex architecture and engineering project, the new plant will be made real following the BIM (Building Information Modeling) methodology, a process that is based on a smart database that is updated in real time with each advance of the project and that allows to visualize of possible way simultaneously the possible changes.

Source: Fly News